"Intelligent Manufacturing Solution Innovation Competition Launching Meeting" was held in Beijing

January 27, 2024

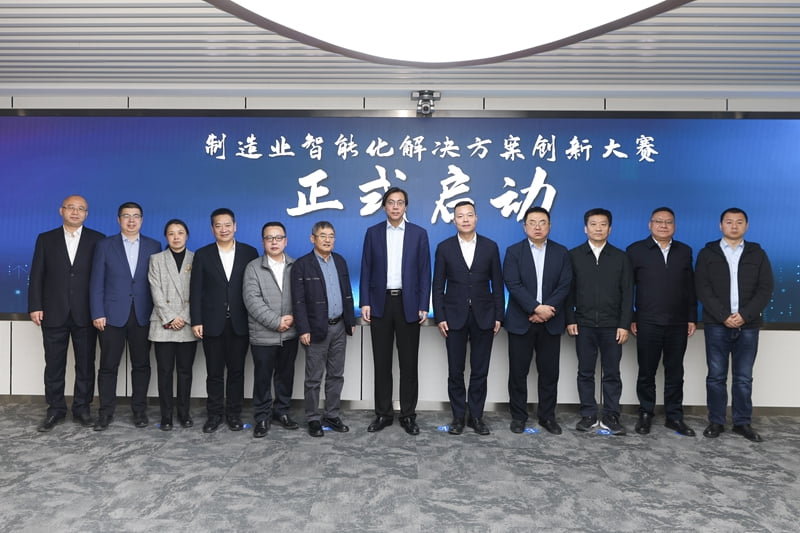

A reporter from China Securities News learned that on January 25, the "Intelligent Manufacturing Manufacturing Solution Innovation Competition Launching Meeting" was held in Beijing. Guests attending the meeting witnessed and launched the Manufacturing Intelligent Solution Innovation Competition. This competition is jointly sponsored by the Central Enterprise Intelligent Manufacturing Collaborative Innovation Platform, the Chinese Expert Committee of the IEC Intelligent Manufacturing System Committee, the Institute of Comprehensive Technology and Economics of Mechanical Industry Instrumentation, and the China Economic Information Service of Xinhua News Agency. The kick-off meeting of the Manufacturing Intelligent Solution Innovation Competition. Photo source: Xinhua News Agency China Economic Information Service Intelligent manufacturing is becoming a key force in promoting the optimization and upgrading of the industrial system. In recent years, our country has accelerated the technological transformation and upgrading of traditional industries and increased the promotion of intelligent manufacturing. It has built 62 "lighthouse factories", accounting for 40% of the total number of "lighthouse factories" in the world, and cultivated 421 national-level intelligent manufacturing demonstration factories, There are more than 10,000 provincial-level digital workshops and smart factories. According to reports, the first manufacturing intelligent solution innovation competition has the theme of "exploiting new productive forces and promoting new industrialization-innovation-driven and empowering intelligent manufacturing". It covers the upgrading of basic manufacturing capabilities, the optimization of key production links, the guarantee of core elements and resources, Intelligent testing equipment innovates 4 tracks. Each track has a first prize bonus of 100,000 yuan, a second prize bonus of 60,000 yuan, and a third prize bonus of 30,000 yuan. Among them, the basic manufacturing capacity upgrade track focuses on digital design simulation, equipment digitization, intelligent production lines, digital twin factories, high-performance industrial networks, etc. The key production link optimization track focuses on dynamic optimization of planning and scheduling, comprehensive quality control, in-factory intelligent logistics, equipment predictive operation and maintenance, intelligent operation decision-making, etc. The core element resource guarantee track focuses on smart supply chain collaboration, energy and carbon lean management and control, data resource management and application, industrial safety integrated management and control, artificial intelligence industrial application, etc. The intelligent testing equipment innovation track focuses on manufacturing process online testing equipment, product quality testing and traceability equipment, equipment operation testing equipment, production safety and environment monitoring equipment, etc.

View More